Metallographic and Chemical Laboratory

The Metallographic and Chemical Laboratory is certified according to ČSN EN ISO 17025:2018 for the fields of chemical, metallographic, and defectoscopic testing of materials.

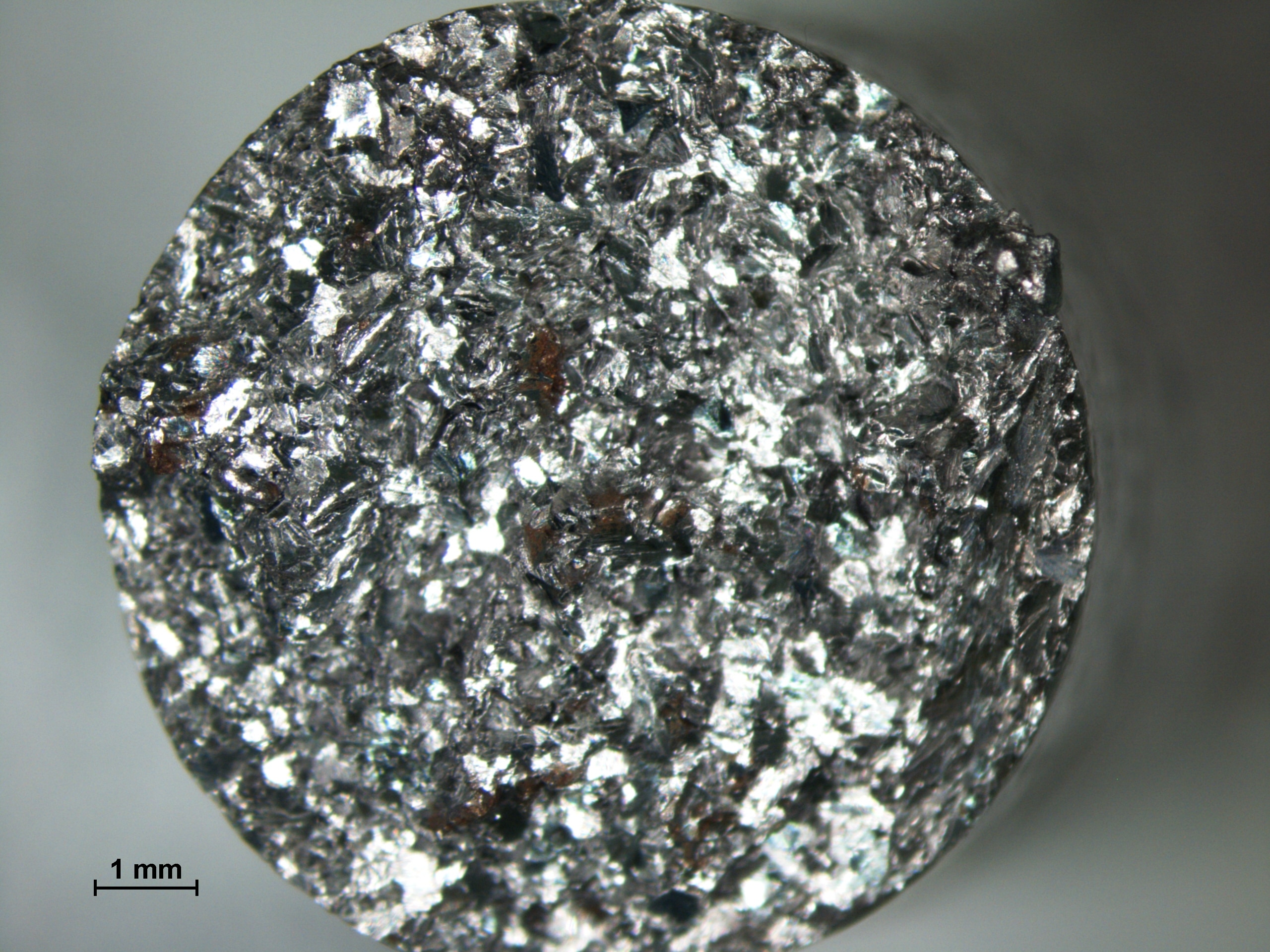

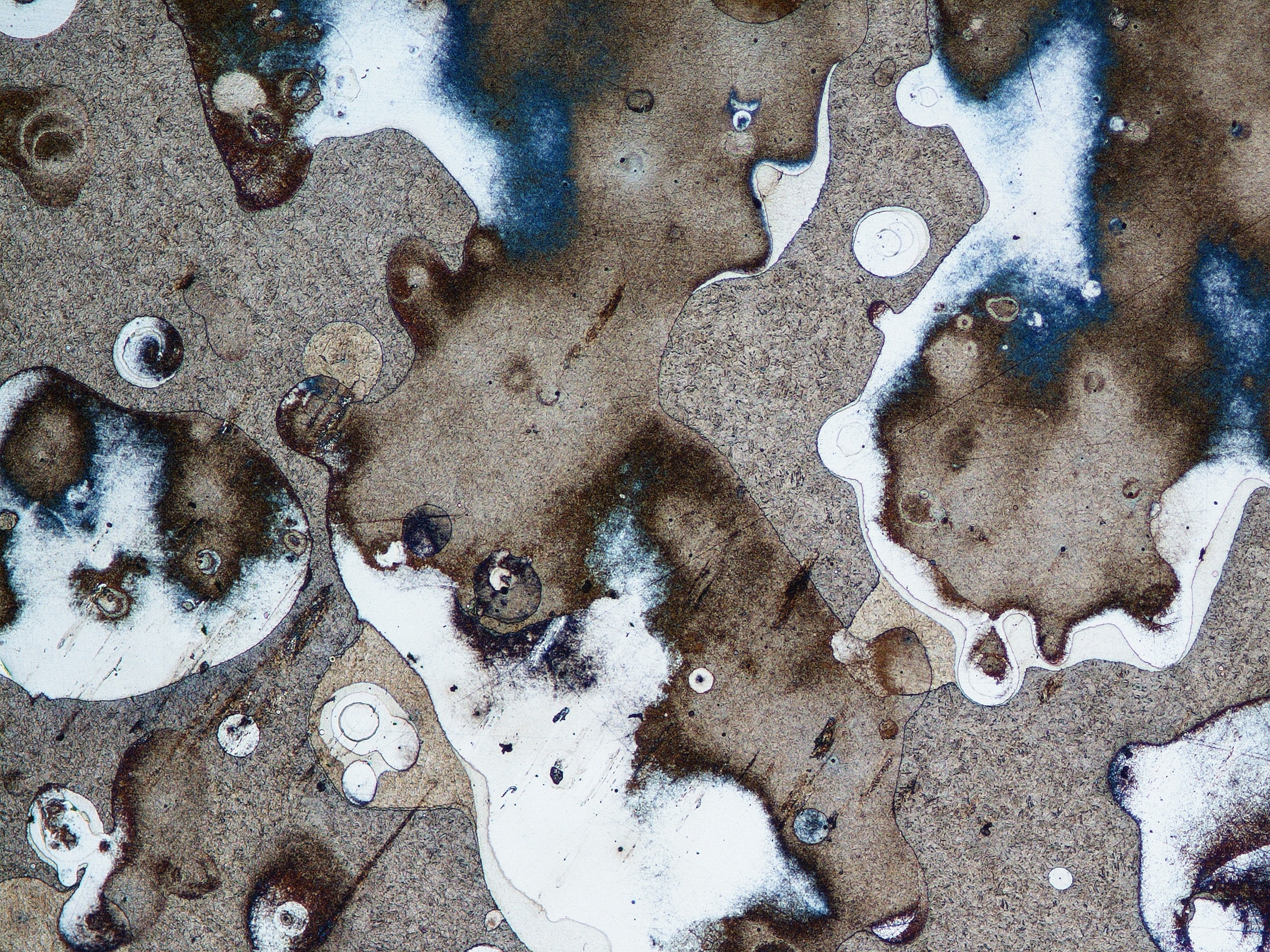

Main offered services include micro- and macro-structure analysis of ferrous and non-ferrous metals, description of structure, and assessment of quality of metallurgic materials. Owing to long history we are experienced in analysis of degradation processes in materials and determination of their residual lifecycle.

We can test the materials at customer’s premise using non-destructive and semi-destructive tests (sampling of a small quantity of material to avoid structure damage). In case of material failure (cracking, distortion) we can come up with detail analysis with description of the proposed solution.

The chemical laboratory staffs are highly experienced in chemical analyses of organic and inorganic substances, and determination of their properties.

- Full analyses of materials including expert review

- Determination of macro- and micro-structure of materials

- Full analyses of production and operation defects

- Review of residual lifecycle of structures and equipment

- NDT of materials and structures

- Check of weld joints

- Analysis of surface treatments, coat thicknesses

- Chemical analyses of metals, alloys, and other inorganic materials

- Identification of organic compounds

- Chemical analyses of plastics, petroleum products, oils, fuels and lubricants

- Determination of properties of liquids (flash point, fire point, heat of combustion, heating capacity)

- Corrosion tests – cyclic, intercrystalline corrosion, potentiostatic measurement

- Consulting activities

- Product sheet

- Fully equipped sample preparation room by Struers

- Olympus PMG 3 and Nikon Epiphot 300 light microscopes

- JEOL JSM 6490 LV scanning electron microscope

- JEOL JEM 1200 EX transmission electron microscope

- Cyclic corossion chamber SaltEvent SC/UKWT 1000

- Q4 TASMAN optical emission spectrometer

- LECO DM-AMH 55 micro-hardness meter

- FTIR, NICOLET 380 infrared spectrometer

- GBC 932 AA atomic absorption spectrometer

- PU 8755/00 spectrophotometer

Our experts pay maximum attention to each job and are always ready to explain test results to customers, and submit description of the proposed solution upon request in order to assist in dealing with complex issues associated with development and production of materials, alloys, and forged pieces.

Serving you since 1901