Thermal Spraying

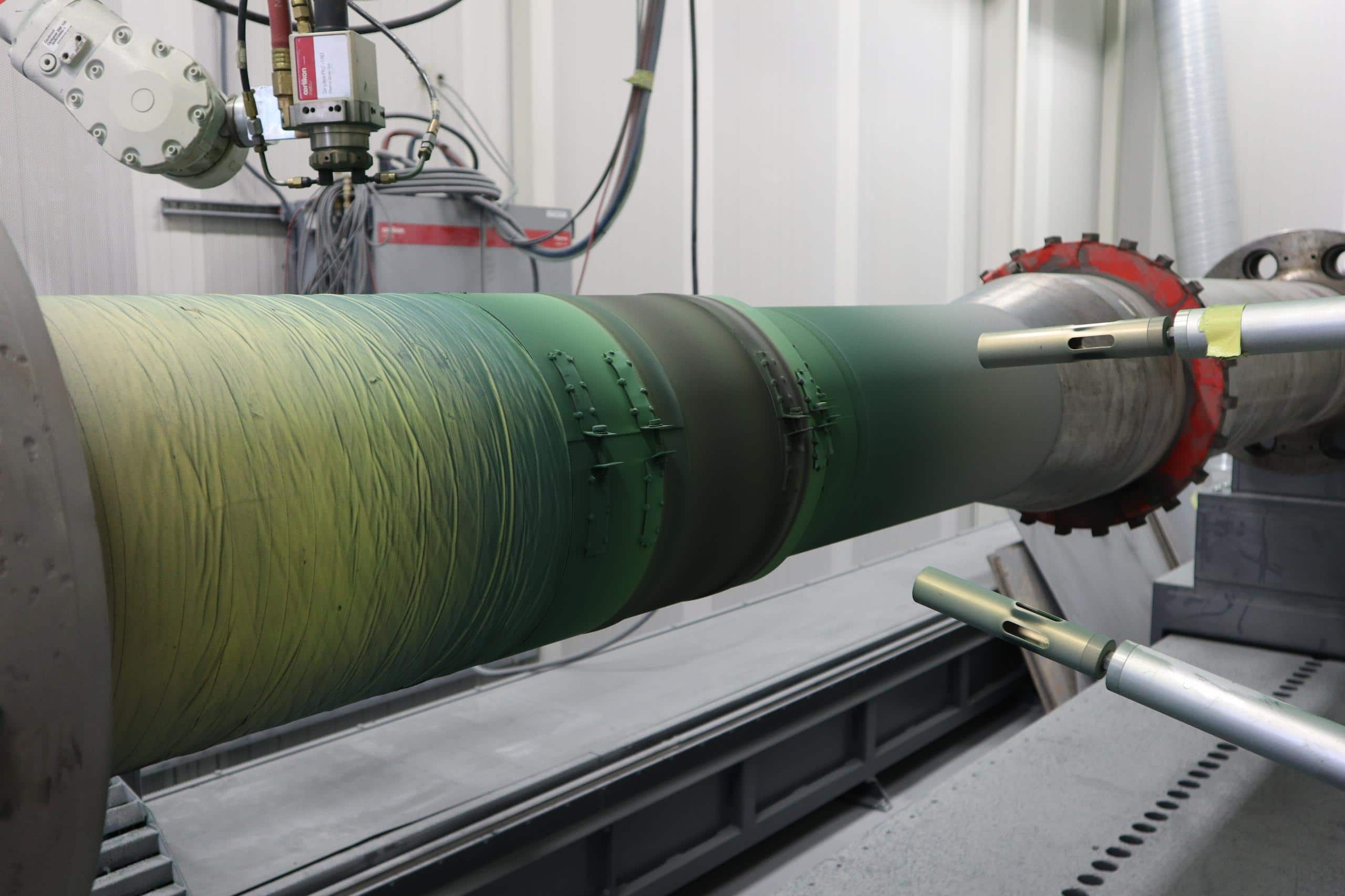

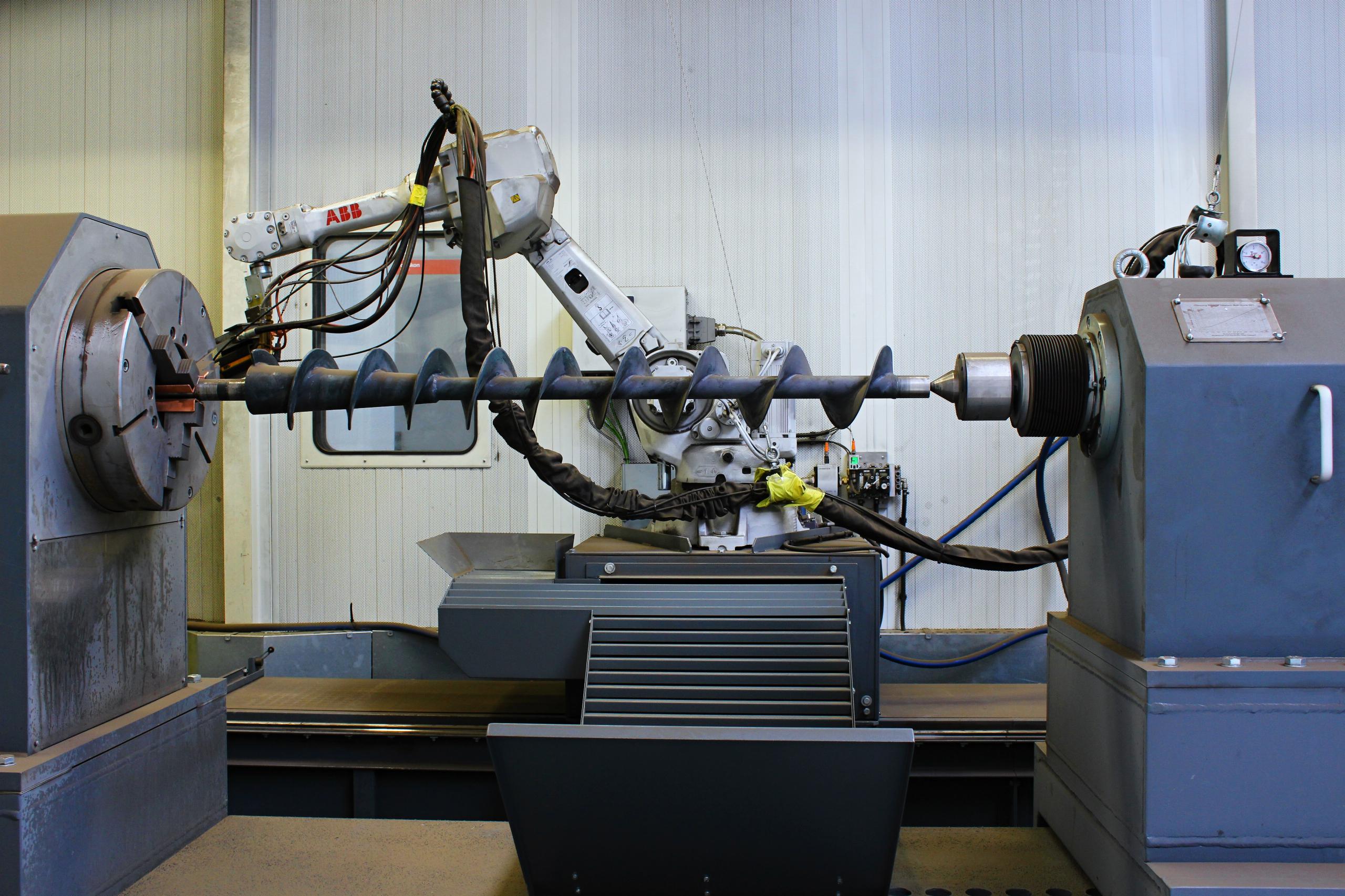

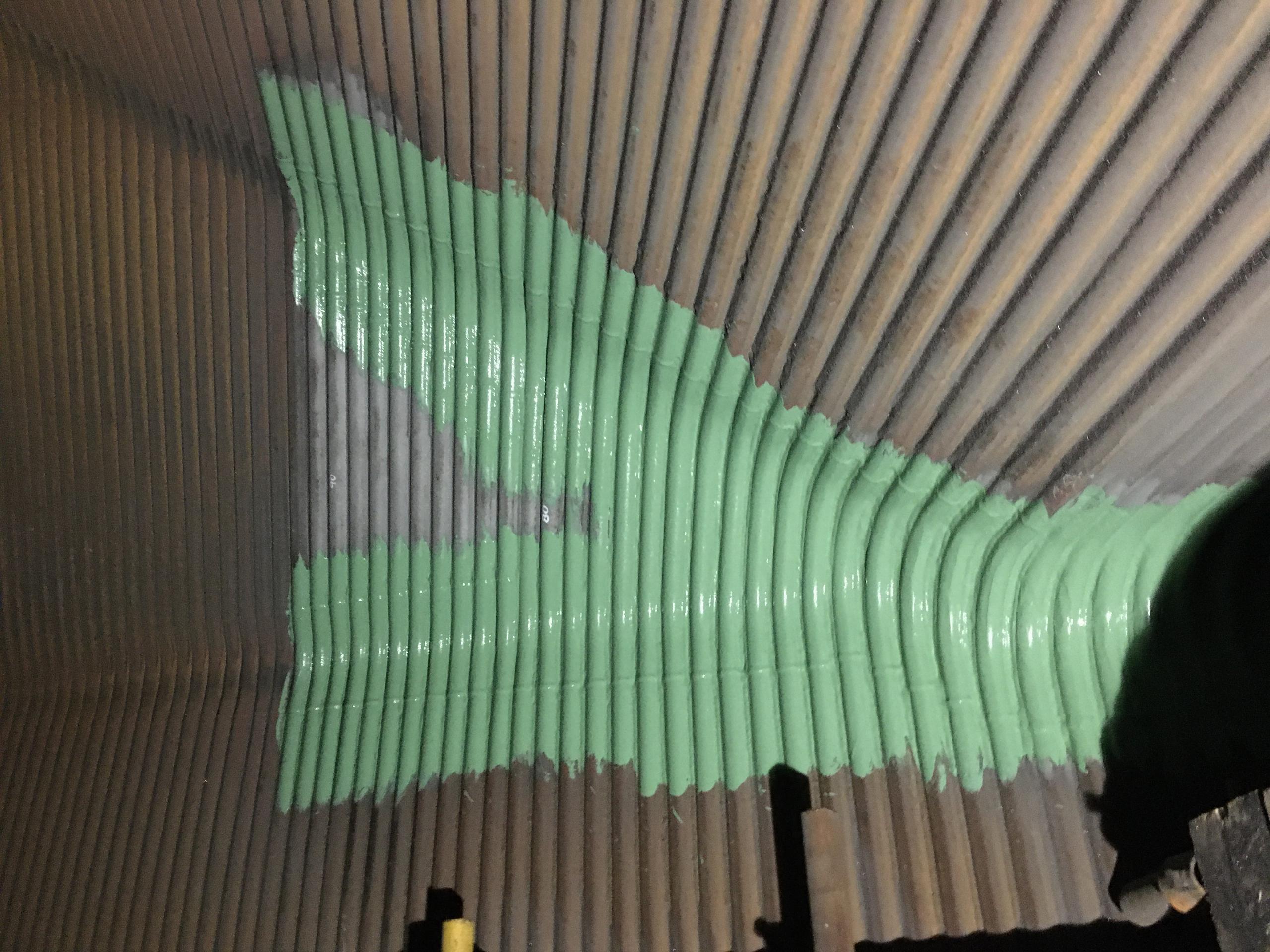

We are active in R&D in the field of thermal sprays including tailor-made production and potential renewal of components. Not only R&D of applications closely related to customer requirements but commercial production is included in our services, which allows us to draw on our experiences from the field of thermal sprays.

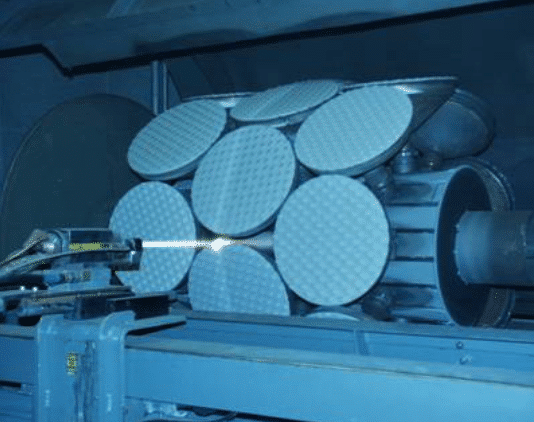

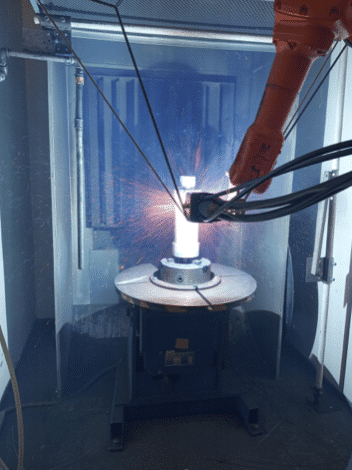

- Application of functional coats by dipping (air plasma spraying (APS), high pressure, high velocity oxy fuel (HP/HVOF) twin wire arc spray (TWAS), flame spray (FS)).

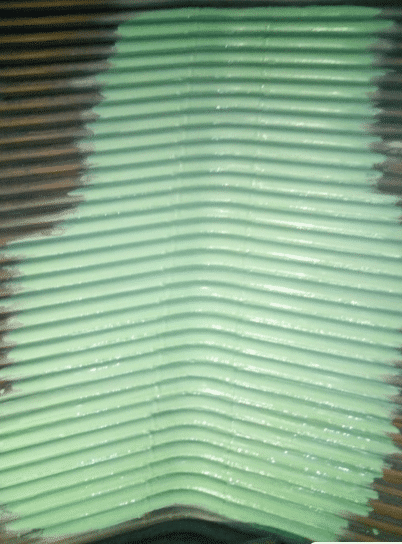

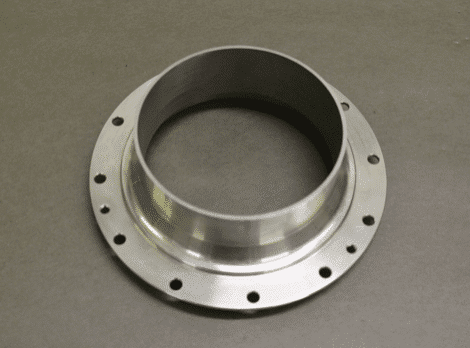

- Functional thermal spray coats resistant to abrasion and erosion wear and tear, high temperatures, corrosion, wear-resistant coats, etc. based on metals, alloys, highly alloyed alloys, metal-ceramic coats (cements), and ceramics. We employ a wide range of commercially available materials but we can assist in development of new materials if required.

- We can apply thermal spray to components having max length 6000 mm, max clear opening 1400 mm and max weight 6000 kg.

- Final grinding available upon request

- We provide one-stop-shop supplies of thermally sprayed components from forged piece to final products

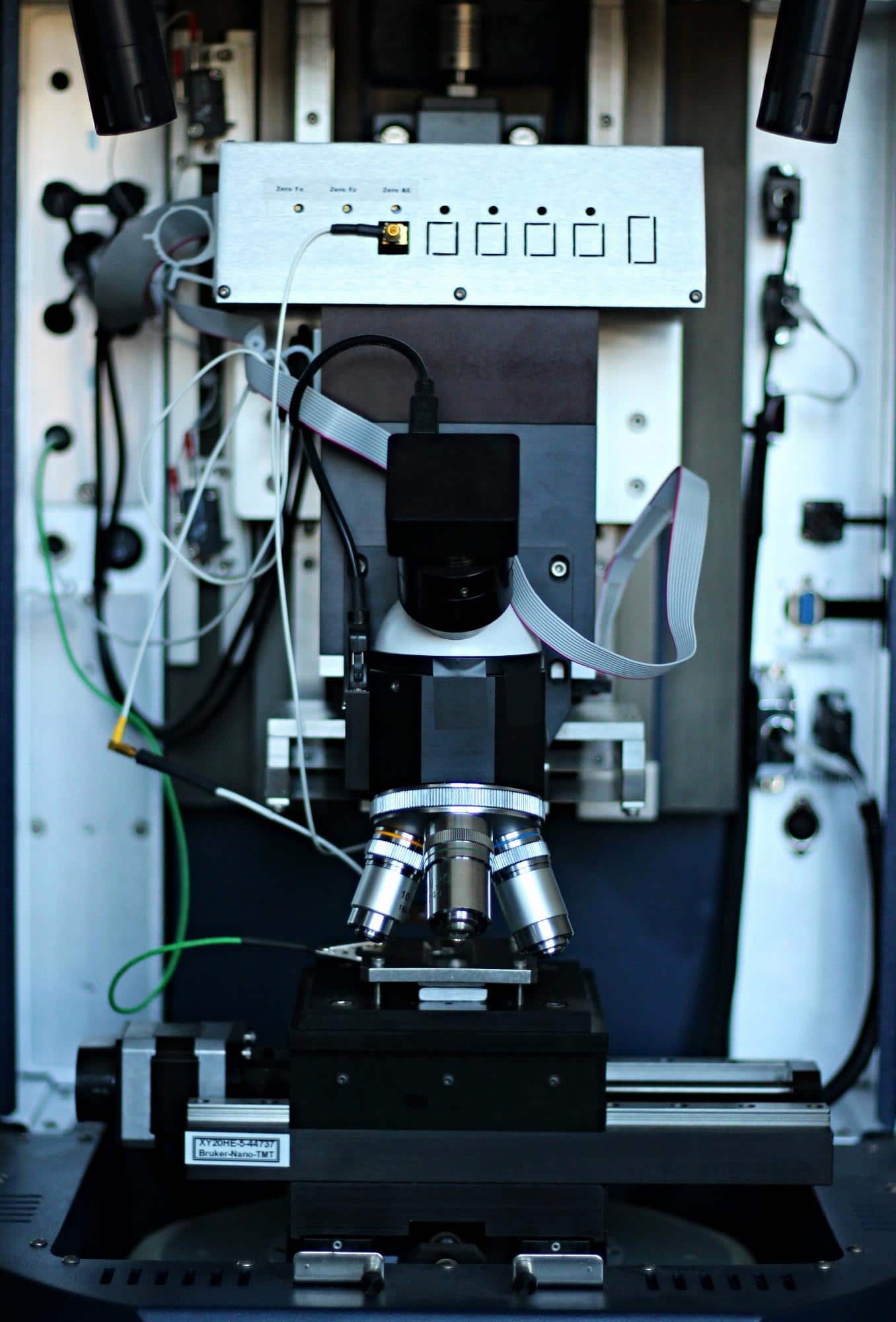

- Technical and R&D support by Surface Treatment Laboratory to check and assess the quality features and tribological properties of materials and coats (testing of abrasion, erosion, and adhesion resistance of materials, corrosion tests, and more)

- Product sheet

- Smart-ARC twin wire arc spray apparatus by Oerlikon Metco and Model 9000 by TAFA Incorporated

- HP/HVOF WokaJet high pressure, high velocity oxy fuel apparatus from Oerlikon Metco and JP 5220 from TAFA Incorporated

- 6P-II flame spray apparatus by GTV and Oerlikon Metco

- Sinplex Pro and F4 plasma spray apparatus by Oerlikon Metco

- Cold Spray Impact Gun 6/11 EvoCSII by Impact Innovations

Apparatus for determination of

- adhesion resistance according to ASTM C633 (surface adhesion measurement)

- abrasion wear resistance according to ASTM G-65 (Dry Sand/Rubber Wheel test)

- linear shear wear resistance according to ASTM G-133 by CETR UMT

- erosion resistance by solid particles

Employees of the Thermal Spraying Department provide customers with comprehensive services in the field of surface protection. The customers may address us with common demands for already repeated or proven coating methods and application thereof, or with queries for brand new problems.

Cooperation with customers routinely performed on longterm basis. The object of the cooperation is bringing new solutions to the customers for their problem both with respect to component lifecycle, wear resistance, corrosion resistance, electric resistance, thermal insulation, or other surface properties. Hence, the cooperation with customers may take place through mutual R&D projects or on regular custom basis that is more or less repeatable.

Finally, the Thermal Spraying Department can assist the customers by announcing a long-term project on a grant basis. These projects are most suitable for for providing new and innovative solutions.

- Replacement of hard chromium plating

- Wear protection

- Corrosion and high-temperature corrosion protection

- Abrasion, erosion, and cavitation protection

- Thermal barriers

- Sliding surfaces

- Dielectric surfaces

- Recovery of surface during renovation of component