Mechanical Laboratory

In particular, the Mechanical Laboratory focuses on testing of essential mechanical properties of, in particular, ferrous and non-ferrous metals as well as plastics and composites, components/semi-finished products, and final products as well.

The Mechanical Laboratory has available in-house shop for production of test specimens and special test jigs.

The tests are mostly certified and conducted according to the standards: ČSN EN, ASTM

Standard tests

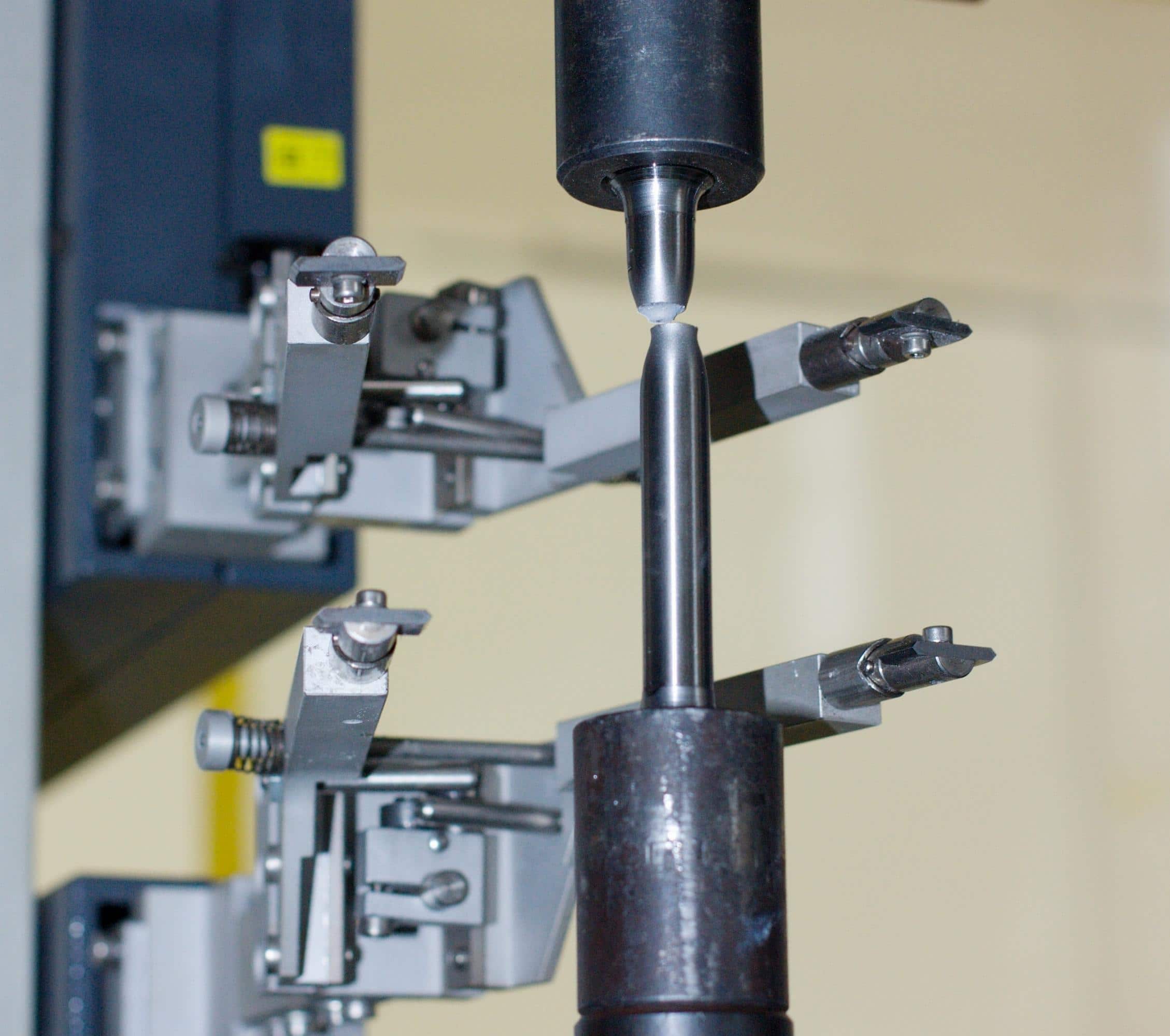

- Tensile test (RT up to 1050 °C) *mini TAH

- Pressure test

- Bend test

- Notch toughness test (-150 °C up to +800 °C)

- Hardness measurement tests (Vickers, Brinell, Rockwell)

Fatigue tests

- Low-cycle fatigue

- High-cycle fatigue (RT up to 1050 °C)

Fracture toughness tests

- KIC

- J-R Curve

- Fatigue crack propagation speed measurement

- Determination of threshold value of strain intensity factor for fatigue crack propagation

Creep tests

- Creep test – tests with measured elongation

- SR test

- Relaxing tests

Special tests

- Mini Tensile Test – analogy of classic tension test conducted on a mini test body Very low quantity of the material is needed. The results are comparable to results obtained with the use of a standard sample for tensile test.

Engineering Production

- NC milling

- Cutting Wire cutting

- Flat and round grinding

- Surface finishes, and more according to agreement with customer

- We produce bolts, nuts, pins, nozzles, rivets, sleeves, rings, test bodies, and more

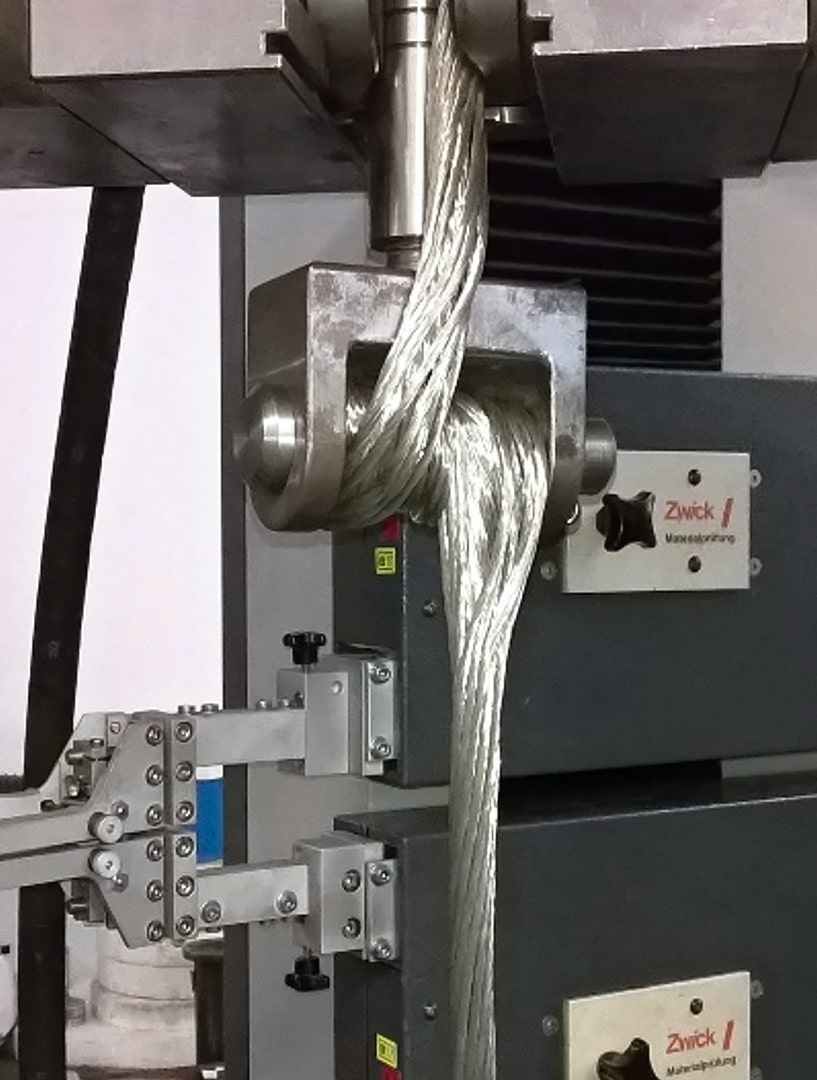

ZWICK, INSTRON, Schenck-Trebel test apparatuses with loading capacity from 2 N to 600 kN

Shuttle impulse hammers WPM

WOLPERT, Vickers Armstrong, WPM, and INSTRON (portable) hardness metersCreep laboratory with in-house test apparatus for testing up to 1100 °C temperature and up to 30 kN load

Two turn benches from 1mm to 12mm

One NC lathe with 8-position Duplomatic head, range from 1mm to 100mm, production length 600mm

Two NC lathes with 8-position Duplomatic head, range from 1mm to 200mm, production length 1,000mm

One lathe with digital measurement sui 32, range from 1mm to 100m, turning length 600mm

One SN40 lathe, turning length 600mm, from 10mm to 150mm, and fine milling using a standard milling machine

Broaches, mills, grinders, saws, cutters, and more.

Transport of material for test

Customer arranges for transport at their costs or may use automatic pick-up service for free. Customer only packs the material/VZUP will pick it up, perform required tests, and send back the protocols with results to the customer.

Delivery date

Regarding common jobs, we deliver the results to the customer in 3–5 business days. Individual agreement applies to complex jobs.

We can run tests of the test specimens from the tiniest dimensions up to standard sizes. Our staff registers each sample and the procedure selected by the customer is followed, i.e. the tests may be run under strict parameters of the determined standards and certification, up to individual configuration of the test parameters according to desire of the customer.

We pay detail attention to all jobs. In particular, we focus on small-lot jobs. Where many companies reject you, we are ready to help, including expert assessment of the material embodiment.

Mechanical tests; creep tests

Doosan Škoda Power s.r.o.

Creep tests

Doosan Babcock Ltd.

Mechanical tests

ČEZ

Creep tests

ETD Consulting

Mechanical tests

PILSEN STEEL s.r.o.

Mechanical tests

CZECH PRECISION FORGE a.s.

Mechanical tests

Seele pilsen s.r.o.

Mechanical tests

ŠKODA JS a.s.

Mechanical tests

BRUSH SEM s.r.o.

CTOD tests of fracture toughness of metal sheets under low temperatures

ISD HUTA CZESTOCHOWA SP. ZOO

Specific mechanical tests of rivets for automotive

Yanfeng Czechia Automotive Interior Systems s.r.o.

Mechanical tests

Shape Corp. Czech Republic